Sprout Project Labs

Taiwan Tech Dept. of Chemical Engineering Capstone Teaching Laboratory

Intelligent Chemical Process Laboratory

Introduction

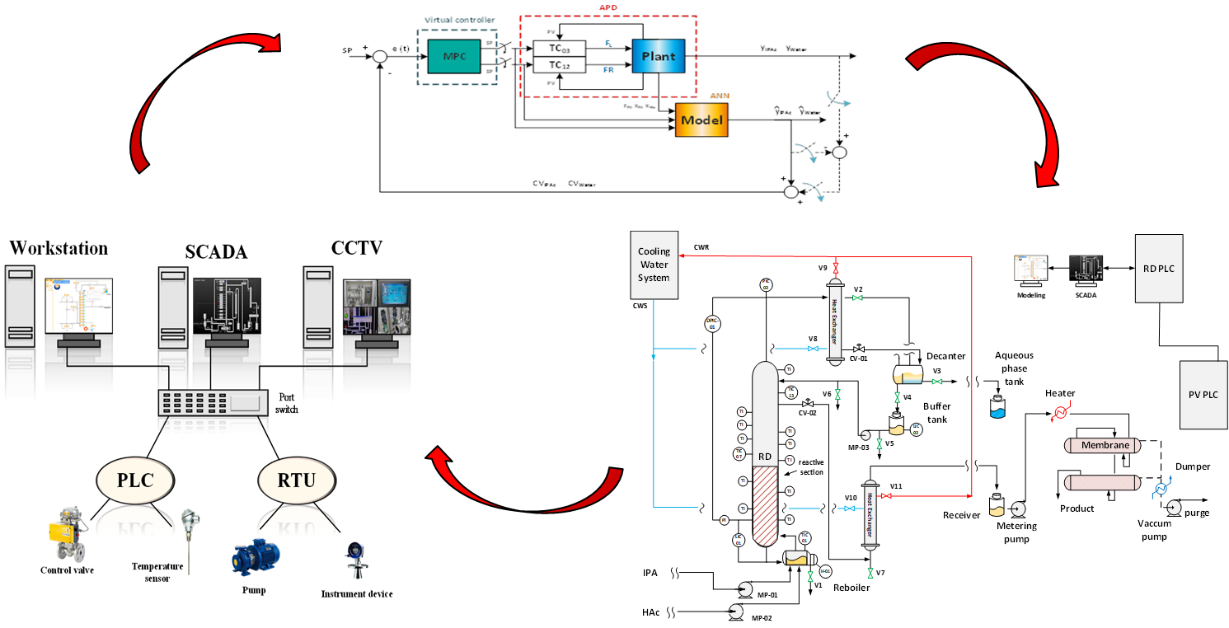

With the advent of the Industry 4.0 era, traditional industrial production methods urgently need transformation. Currently, process simulation technology is rarely used to assist on-site operations or solve practical problems. Furthermore, although Advanced Process Control (APC) or Model Predictive Control (MPC) technologies were once popular in Taiwan, they are seldom seen in domestic chemical processes today due to the complexity of control theory calculations and a lack of understanding regarding operational parameters. Therefore, by establishing dynamic models through rigorous simulation and pre-designing/tuning MPC controllers to develop intelligent operational guidance strategies, we expect to significantly improve the operational performance of actual plants.

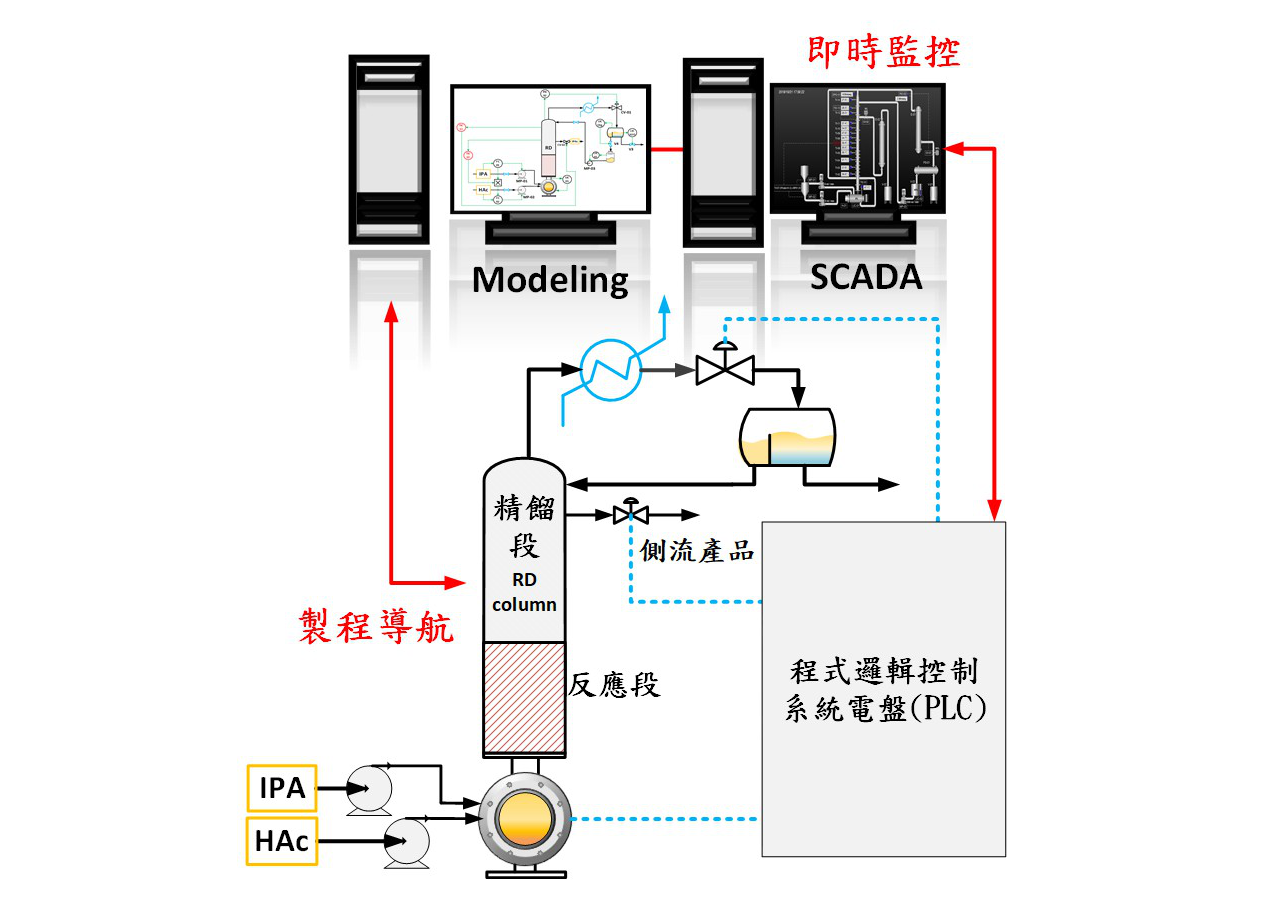

Schematic of Process Prediction and Navigation

Exterior of the Intelligent Pilot Plant

Pervaporation Membrane System

Reactive Distillation System

Pilot Plant Control System Interface

Green Process

This project focuses on the Isopropyl Acetate reactive distillation pilot plant established by the Department of Chemical Engineering at NTUST. An Artificial Neural Network (ANN) model was developed to explore the differences between intelligent operational guidance and traditional PID control, utilizing a cyber-physical integration to enhance experimental results. Reactive distillation combines thermal separation in a distillation column with chemical reactions to achieve continuous unit operations. Compared to traditional physical separation, it offers advantages such as overcoming equilibrium limitations, increasing conversion rates, reducing energy consumption, and lowering equipment/operational costs. In the global semiconductor supply chain, Isopropyl Alcohol (IPA) is widely used for wafer drying and dust removal, generating large amounts of waste liquid. To effectively recycle IPA, reactive distillation is used for esterification combined with pervaporation membrane dehydration to produce high-value esters. While raw IPA costs approximately 1€/L, Isopropyl Acetate can sell for over 100€/L. Isopropyl Acetate is a crucial industrial solvent used in cellulose, coatings, printing inks, and as an extractant in pharmaceuticals. Professor Lee, in collaboration with CTCI ASI, promotes the esterification of treated IPA with acetic acid to synthesize Isopropyl Acetate. This not only aligns with green industry goals but also enhances the international competitiveness of the domestic chemical industry.

Conceptual Design

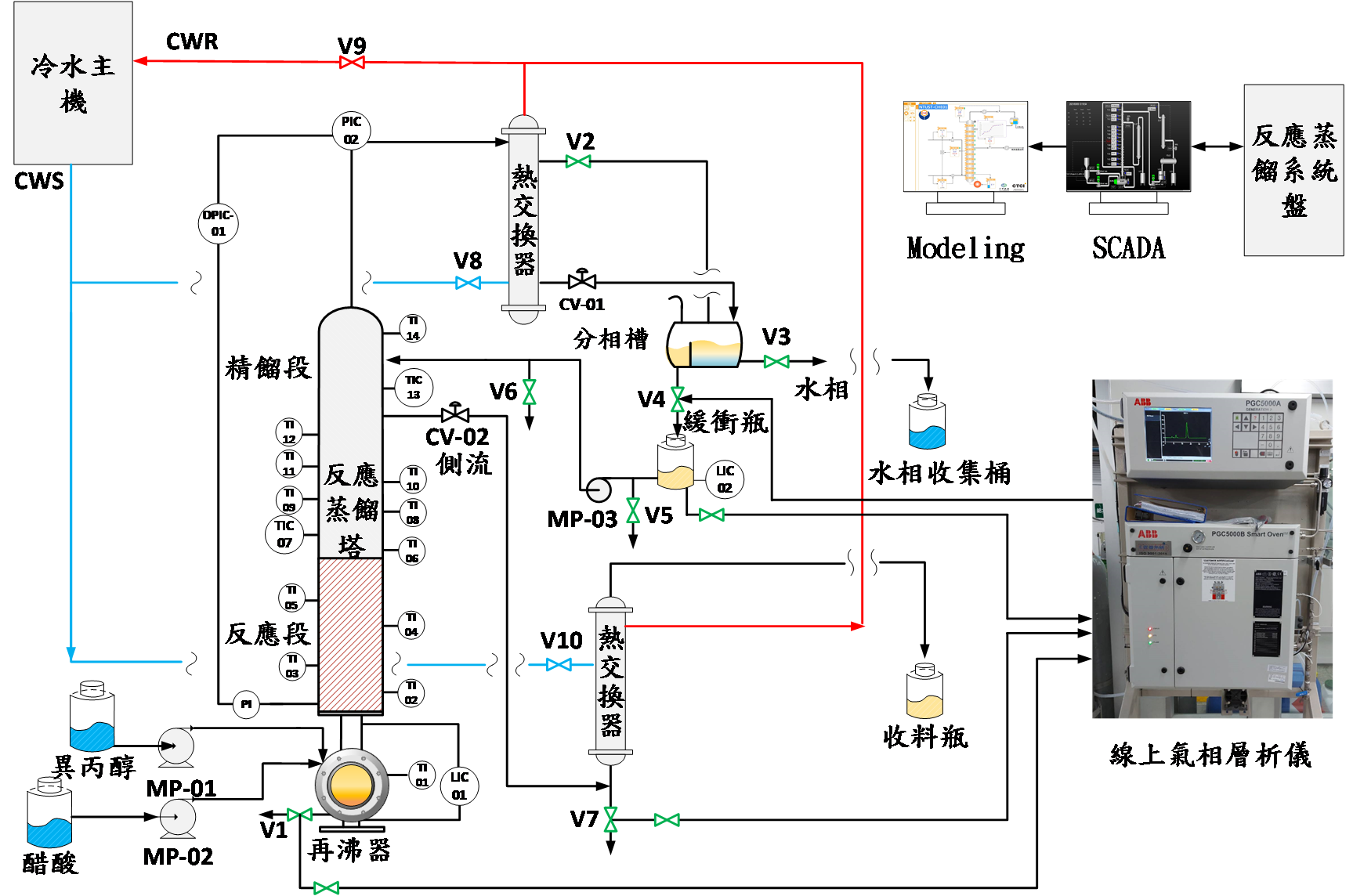

Reactive Distillation Process Flowsheet

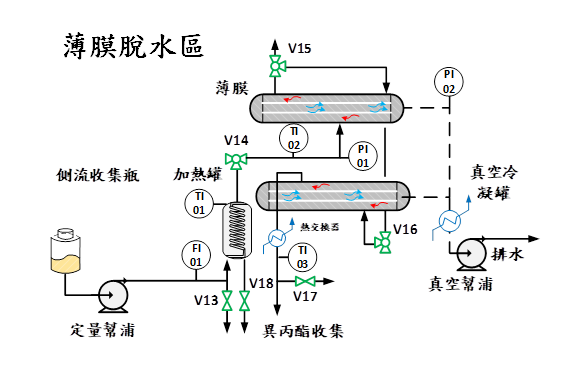

Membrane Process Flowsheet

The pilot plant system is divided into a reactive distillation zone and a membrane dehydration zone. Aspen Plus was used for the design and simulation of the esterification process. In the simulation, IPA and acetic acid are pumped into the reboiler. The reaction section, packed with Amberlyst 39wet, is located between the bottom and the 15th tray. Above the 15th tray is the rectification section, with a side stream at the 4th tray for the primary product. The overhead vapor is fully condensed and sent to a phase separator for organic phase separation and reflux. The side stream, containing trace water, is introduced into a preheating tank and then into the pervaporation membrane. A vacuum pump provides the driving force for separation, ultimately achieving 99.5 wt% Isopropyl Acetate.

Cyber-Physical System (CPS)

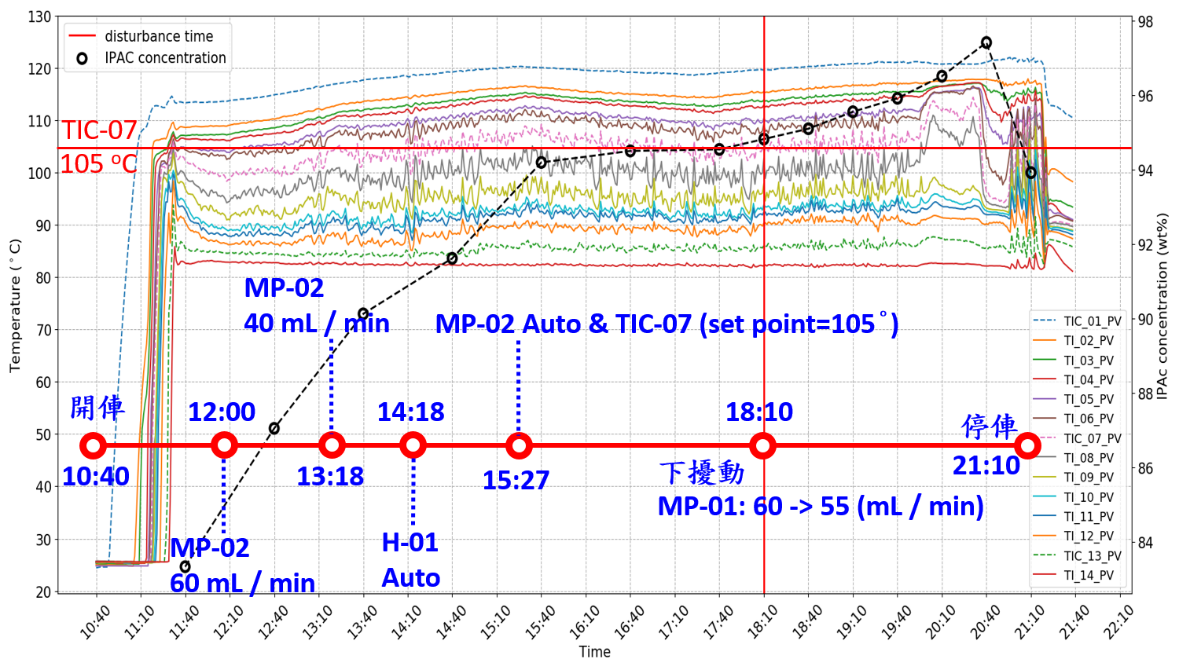

Cyber-Physical System (CPS) is a key technology of "Industry 4.0" and a highly discussed topic. It integrates computers, sensors, and new-generation network technologies to connect equipment, machines, and digital systems, achieving seamless integration between virtual and physical worlds through mutual communication. Decades ago, Taiwan's chemical industry introduced automatic control systems, realizing the vision of Industry 3.0. While the chemical and petrochemical industries are highly complex, the development of computer technology now allows for the analysis of seemingly chaotic process variables. Professor Lee's research team utilized Aspen Plus Dynamics and pilot plant data to establish dynamic models for Isopropyl Acetate reactive distillation, providing on-site operational guidance through model prediction. All signals from physical control instruments are calculated via virtual controllers and displayed on a CPS web system designed by CTCI ASI. When disturbances occur, the ANN system predicts trends and provides setpoint suggestions for quality controllers. Study results show that under a ±10% throughput disturbance, PID control leads to a sharp drop in product concentration, whereas intelligent guidance quickly provides recommended temperature values, maintaining high product purity through adjustments every 5 minutes. This research helps reduce human error and monitoring installation costs, with the CPS model expected to extend to other chemical processes in the future.

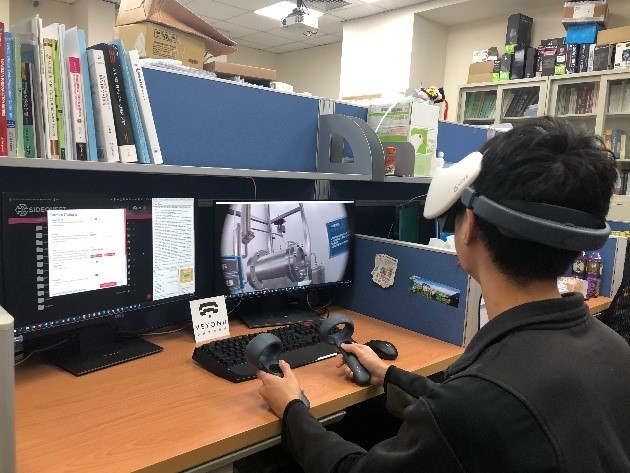

Reactive Distillation VR Virtual Classroom

- Teaching startup procedures for the reactive distillation system, providing efficient training for steps such as pre-startup inspection, commissioning, and shutdown.

- Experimental simulations with different variables and startup procedure testing.

- Emergency response testing to ensure students can handle real-world situations safely.

Implementation and Teaching Outcomes

- Before experiments, students review core courses: Organic Chemistry (esterification), Chemical Engineering Thermodynamics (multicomponent property analysis), Chemical Kinetics (catalytic reaction kinetics), Unit Operations and Transport Phenomena (distillation columns, heat exchangers, piping), Process Control (PID control, variable analysis), Process Design (Aspen Plus), and Digitalization/Intelligence of Chemical Processes (Smart Plant P&ID and Smart 3D).

- Students study the system principles and manuals beforehand. Experiments are conducted in groups of four using a shift system. Students are responsible for assigned tasks and must hand over duties to the next shift. Teaching assistants provide training on starting the intelligent plant and achieving steady state, covering control software, column operation, GC analysis, and pervaporation.

- TAs ask questions based on real-time data and principles to deepen understanding and train emergency response skills, prioritizing safety.

- Once at steady state, throughput disturbance tests are performed using traditional PID control followed by advanced process control (ANN-based guidance). Students record setpoint changes and compare trends with Aspen Plus Dynamics simulations.

- Post-experiment, groups report on steady-state results and comparisons with simulations, training data analysis skills. Feedback on process technology and equipment improvements is also required.

- Disturbance tests demonstrate that advanced process control is more stable, with product concentration less affected than traditional PID control.

Experimental Operation

Software Data Discussion

Final Results Presentation

Product Concentration Graph

Student Practical Competence Assessment

- Oral questioning on technical operations and reactive distillation principles.

- Evaluation of teamwork and coordination within the shift system.

- Performance assessment on operational skills and the ability to complete plant startup within the allotted time.

- Judgment based on whether final product concentration meets specifications and the quality of data analysis.

- Review of final group reports to confirm familiarity with the experiment.

Industrial Collaboration Resources

This pilot plant is a joint research effort between the Taiwan Tech ChE Department and CTCI ASI. The company assisted in bridging SCADA with the Modeling OPC server for real-time data export and calculation, displaying recommended operation values on the CPS web interface via Matlab/Simulink ANN predictions. This facility serves as a showcase for intelligent process analysis and talent cultivation.

In collaboration with CTCI Corporation, the department offers a "Digitalization and Intelligence of Chemical Processes" course. The curriculum focuses on Process Flowsheet Diagrams and Piping and Instrument Diagrams (P&ID), taught by industry experts from CTCI. Students learn to use Smart Plant P&ID for digital process mapping and Smart 3D for plant design, enhancing their ability to understand intelligent plant configurations and operations.

Schematic of SCADA System

CTCI Foundation and CTCI ASI Collaboration Team

Field Trip to CTCI Corporation (Process Design Course)

Industry-Academic Exchange at CTCI Corporation

Other Significant Achievements

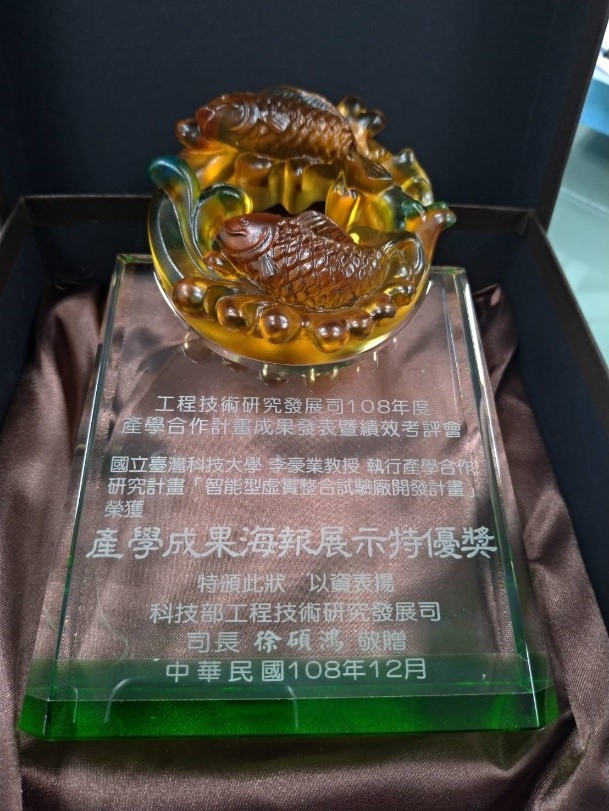

- Recipient of the "Outstanding Award" at the 2019 Industry-Academic Achievement Poster Exhibition, Department of Engineering and Technologies, Ministry of Science and Technology (MOST).

- 2019 Taiwan Institute of Chemical Engineers (TwIChE) Chemical Engineering Masterpiece Award.

- Taiwan Tech 2018 & 2019 Capstone Teaching Laboratory Excellence Unit Award.

Visit from Taichung Industrial High School

Visit from Hsinchu Industrial High School

MOST Industry-Academic Poster and Certificate (Outstanding Award)

MOST Engineering Department Achievement Exhibition

Excellence Unit Plague for Capstone Teaching Lab

TwIChE Chemical Engineering Masterpiece Award